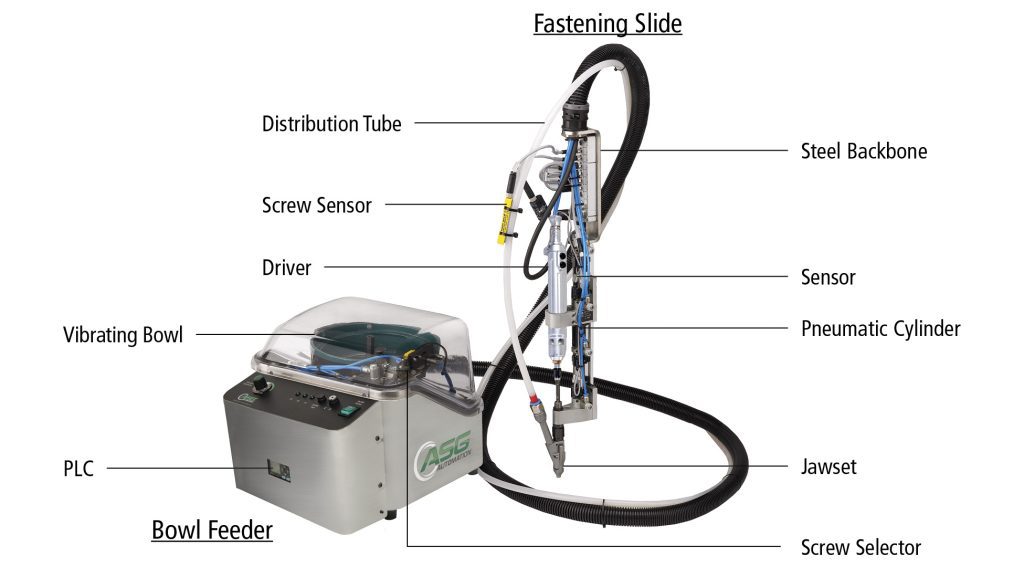

Premium Auto Feed System

Increase production and decrease cycle time and labor costs through speed, reliability, ease of use and maintenance. The system is very swift, delivering a screw to the jaw set in less than half a second. Because of the simple design, the system is also reliable and consistent, providing a virtually jam-free operation. The system also has multiple access panels that may be removed without tools for easy maintenance.

Vibratory Bowl Feeder

Precisely aligns the screws and presents them to the screw selector. Wherein, they are rapidly dispensed into the distribution tube. Finally, a blast of air propels the screw past the screw sensor and into the jaw set. The PLC, signaled by the screw sensor, initiates the driving sequence. Dependable screw feeding is managed by the PLC to optimize all machine parameters.

Customizable Nose Piece & Jaw Set

The nosepiece holds the screw blown from the bowl feeder and guides it toward the workpiece, enabling the bit to engage the screw and fasten the components. The bit engages the fastener, eliminating the fastener pushing back into the jaw set.

Available as a manual auto feed system or integrated into an automation cell.