Accessories for Automated Drivers

Extend the functionality and usability of your screwdriver or nutrunner in an automation system with additional accessories.

Extend the functionality and usability of your screwdriver or nutrunner in an automation system with additional accessories.

BLF Compatible Power Supplies

BLT-AY-61

BLT-AY-71

CL-A and CLF Compatible Power Supplies

Additional options available, however, cannot be added after purchase:

CLT-AY-61: Compatible with CLF-3000, CLF-4000, CLF-6000, CLF-6500, CLF-7000

CLT-AY-81: Compatible with CL-816A, CL-825A, CL-850A

HIOS HM Digital Torque Testers

Comes with certificate of calibration traceable to N.I.S.T. and enables easy calibration of screwdriver without removing from machine.

2 modes of operation:

220V available

Torque accuracy: +/- 0.5%

64033

64034

Uses negative pressure to reduce the need to pick-up screws. The suction attachment can pick up non-ferrous screws such as stainless steel screws. Vacuum attachments can improve efficiency and be used to remove powder dust generated from screw tightening.

Contact Us for additional information.

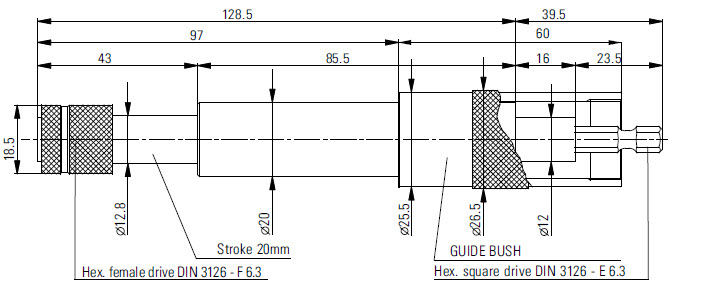

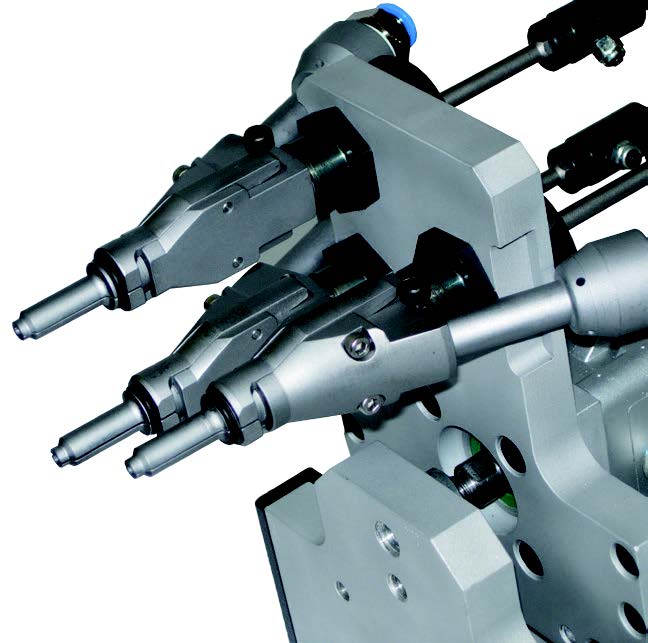

Fastening slides are important components equipped with an air nutrunner motor, screw head, bit and bit holder; suitable for use in semi-automatic or automatic industrial tightening solutions.

These linear actuators are designed entirely by Fiam and are manufactured with the highest quality materials. This guarantees high reliability and resistance over time.

Available in 3 different options:

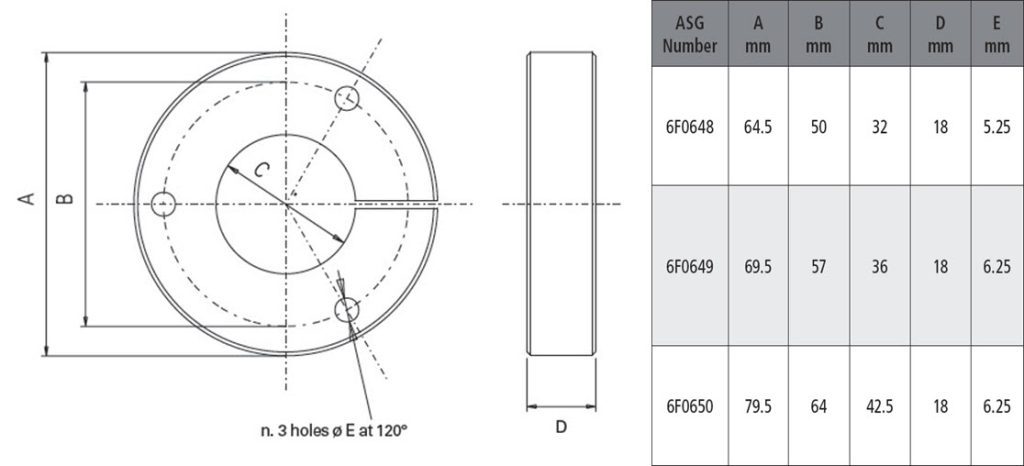

We recommend using the 3-hole flange bracket to install a nutrunner motor for screwdriving applications on a fixed mounting. This avoids the possibility of any operating problems since it acts on the entire circumference of the motor casting.

6F0648

6F0649

6F0650

This component is required to receive the screw coming through the feeding tube from the bowl feeder. The design of the screw head ensures that the screw remains properly aligned ready to engage the bit and work piece.

Screw heads are extremely reliable as they are built with highest quality materials through precise and accurate machining. Together with the treatments, this guarantees high resistance to breaking and wearing.

Available in various models suitable for multiple screw types, these heads are further tailored and machined by Fiam based on the design of the customer’s screw.

Ease entry of screw and reduce axial thrust on the motor’s mechanical components. When fastening more screws simultaneously, the axial compensation device in the bit compensates for the differences in height between the screws before starting the tightening process.

6F0881

6F0623

6F0624